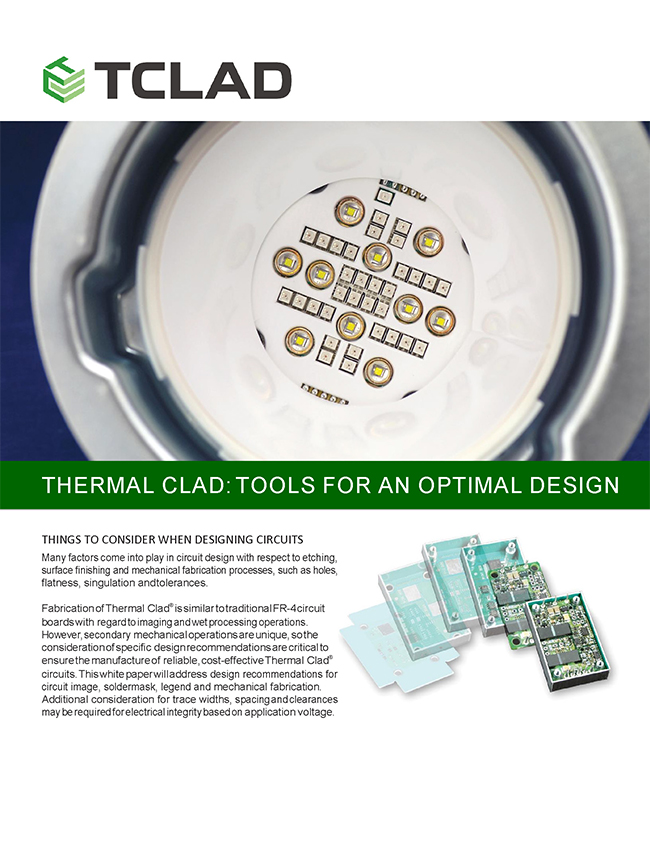

Tools for Optimal Design

While Insulated Metal Substrate (IMS®) circuit board fabrication shares some similarities with traditional FR4 processes — particularly in imaging and wet processing — it involves distinct secondary mechanical operations that require specialized attention. Designing reliable, cost-effective IMS® boards demands careful consideration of fabrication factors such as etching, surface finishing, hole formation, flatness, singulation, and mechanical tolerances.

Design Support

To help designers tackle unique challenges, we’ve developed a comprehensive design guide and a powerful, software-driven thermal calculator. These tools assist engineers in optimizing critical design parameters — such as trace widths, spacing and electrical clearances — to improve performance and manufacturability. And if you ever get stuck on a tricky design detail, our technical team is just a call or click away — ready to help you move forward with confidence.

Contact UsNeed More Help? Contact our technical support team.

Optimized Design Starts Here

This comprehensive 10-page white paper presents essential design guidelines covering key aspects of IMS® PCB layout, including circuit imaging, soldermask application, legend printing, and mechanical fabrication. It also offers essential considerations on trace widths, spacing and clearances to support electrical integrity, manufacturability, and overall performance — while highlighting strategies to help minimize cost.

If you have questions or need guidance on implementing these design recommendations, TCLAD’s technical support team is here to help. Our experts are ready to provide personalized assistance. Don’t hesitate to reach out for support at any stage of your project.

Download

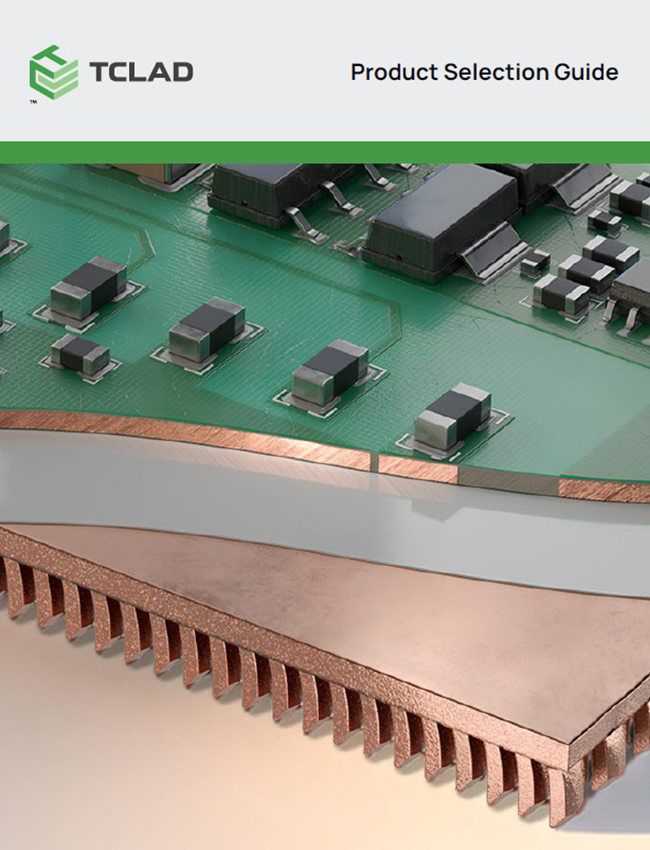

TCLAD Product Selection Guide

This 24-page guide provides detailed information to help you select from our most popular TCLAD dielectrics and metal base plates. It includes a case study on converting an FR4 PCB to an IMS®/ Metal Clad PCB, a variety of real-world application examples, and key data on electrical and thermal performance. Backed by over 50 years of global expertise, our multi-award-winning formulations provide essential heat dissipation across a wide range of markets. Explore our flagship offerings — including IMS®, Thermal Clad, and specialty circuit structures — to inspire your next design.

DownloadTCLAD’s Thermal Calculator

Calculating temperature rise due to current resistive heating (I2R losses) in an IMS® PCB is crucial for minimizing circuit temperature under full load. Unlike FR4 and other conventional PCB materials, IMS® circuits exhibit significantly lower temperature rise due to their high thermal conductivity. This tool helps optimize the thermal dielectric and copper weight combination to best suit your application, balancing electrical and thermal needs to maximize performance and minimize cost.

TCLAD’s Thermal Calculator is a FREE to use software that empowers designers to optimize IMS® PCB designs with greater speed and efficiency. Just input material and circuit parameters and the tool calculates the temperature rise in the circuit. It is compatible with virtually any computer system, including Windows, Linux, and MacOS — making it accessible to a broad range of users.

Unlock the Power of TCLAD’s Thermal Calculator

Fill out the form below to receive FREE access to our Thermal Calculator and start optimizing your IMS® PCB design for peak thermal performance.

TCLAD Inc. U.S. Mfg & Global

Innovation Center

1600 Orrin Rd, Prescott

WI 54021 USA

Phone: +1 715 262 5898

Email: sales.us@tclad.com

TCLAD Europe GmbH

Amelia-Mary-Earhart-Str. 8, 60549

Frankfurt am Main, Germany

Phone: +886 3 5635598

Email: sales.eu@tclad.com

TCLAD Technology Corp.

1 F., No. 5, Gongye E. 7th Rd.,

East Dist., Hsinchu City 300093,

Taiwan (R.O.C)

Phone: +886 3 5635598

Email: sales.asia@tclad.com