Thermal Clad Dielectrics

Strategically Engineered & Patented

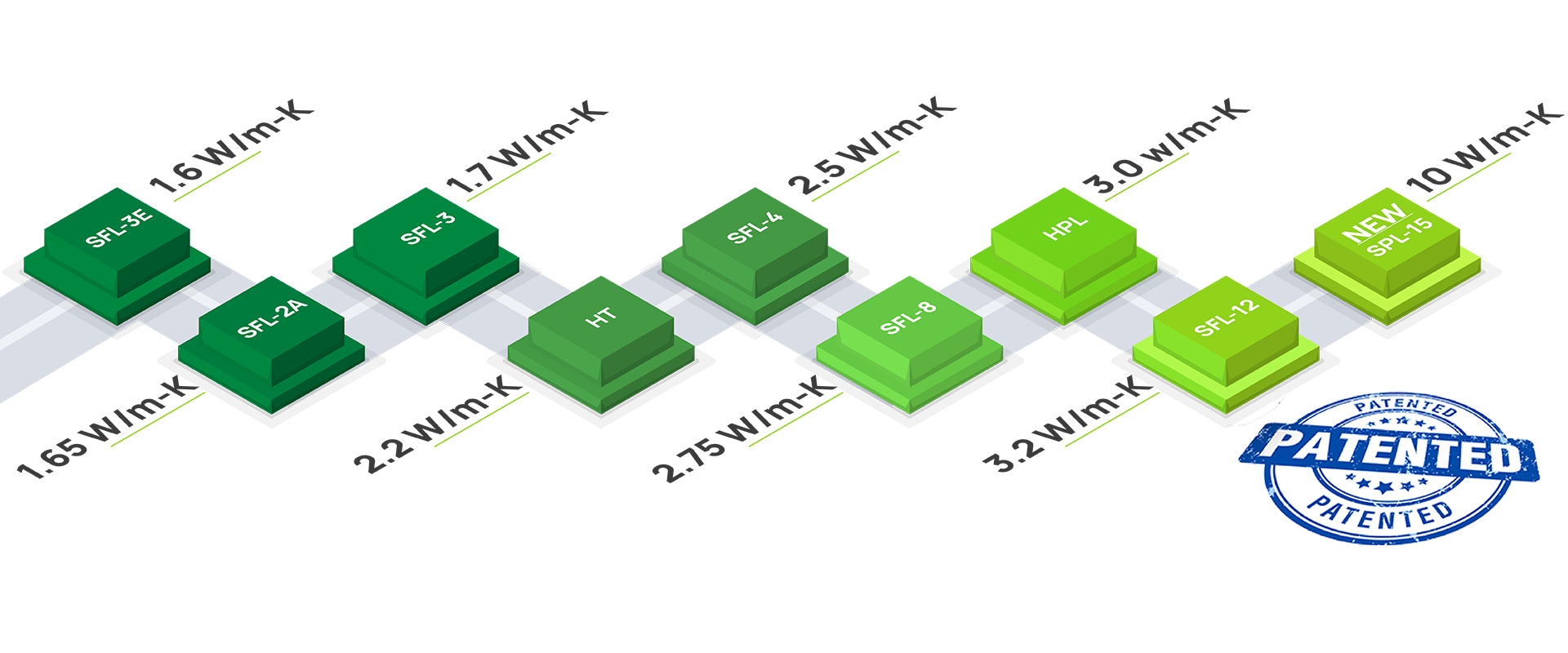

TCLAD offers the industry’s most extensive range of dielectric materials, providing unmatched design flexibility across a variety of PCB formats – from insulated metal substrate (IMS®), to prepreg (PP) composites, thin core series (TCS), and rigid copper-clad (RCC) laminates.

High-Performance Dielectrics by TCLAD

Engineered for High-Power IMS®/MCPCB Applications

Flagship Thermal Clad Dielectric Solutions

Our proprietary dielectrics are engineered to deliver exceptional electrical isolation and ultra-low thermal impedance. Available in a variety of formulations and thicknesses to suit diverse application requirements, these advanced materials enhance performance and reliability where thermal management and electrical insulation are critical.

| Thermal Clad Products | Thickness | Thermal Conductivity (W/m-K) | Thermal Resistance (°C-in2/W) | Breakdown Voltage (KVAC) | Glass Transition Tg (°C) | CTE in XY/Z <Tg (µm/m°C) | CTE in XY/Z >Tg (µm/m°C) | Saftey Data Sheet | Technical Data Sheet |

|---|---|---|---|---|---|---|---|---|---|

| SFL-3E | 4.0 mil (100µm) | 1.6 | <0.13 | 7 | 55 | 24 | 37 | Download | Download |

| SFL-2A | 4.0 mil (100µm) | 1.65 | <0.13 | 6 | 130 | 20 | 30 | Download | Download |

| SFL-3 | 4.0 mil (100µm) | 1.7 | <0.12 | 6 | 140 | 25 | 32 | Download | Download |

| HT | 3.0 mil (75µm) | 2.2 | 0.05 | 8.5 | 150 | 25 | 95 | Download | Download |

| 4.0 mil (100µm) | 2.2 | 0.077 | 9.3 | 150 | 25 | 95 | Download | Download | |

| 6.0 mil (150µm) | 2.2 | 0.11 | 11.0 | 150 | 25 | 95 | Download | Download | |

| 9.0 mil (225µm) | 2.2 | 0.16 | 20 | 150 | 25 | 95 | Download | Download | |

| SFL-4 | 4.0 mil (100µm) | 2.5 | 0.11 | 5 | 55 | 16 | 25 | Download | Download |

| SFL-8 | 4.0 mil (100µm) | 2.75 | 0.08 | 5 | 150 | 28 | 35 | Download | Download |

| HPL | 2.0 mil (50µm) | 3.0 | 0.026 | 7.7 | 185 | 35 | 85 | Download | Download |

| 3.0 mil (76µm) | 3.0 | 0.028 | 9.7 | 185 | 35 | 85 | Download | Download | |

| 4.0 mil (100µm) | 3.0 | 0.031 | 12.2 | 185 | 35 | 85 | Download | Download | |

| 6.0 mil (150µm) | 3.0 | 0.039 | 17.4 | 185 | 35 | 85 | Download | Download | |

| SFL-12 | 4.0 mil (100µm) | 3.2 | 0.06 | 5 | 180 | 15 | 18 | Download | Download |

| SPL-15 | 4.0 mil (100µm) | 10 | <0.015 | 4 | 270 | 11.7 | 24.3 | Download | Download |

| SFLG-8 | 4.0 mil (100µm) | 1.85 | 0.09 | 5 | 150 | 28 | 35 | Download | Download |

| SFLG-12 | 4.0 mil (100µm) | 2.8 | 0.065 | 5 | 180 | 15 | 18 | Download | Download |

Selecting Dielectric Materials

Property values provide valuable insights; however, real-world thermal performance is application dependent. Let our team of experts help you navigate the options and select the ideal dielectric material for your application’s unique power, isolation, and temperature requirements.

Key Benefits of Thermal Clad Dielectrics

- Low z-axis expansion for stability under thermal cycling

- Supports thin stack-up designs for compact assemblies

- Solvent-free, low-VOC options for sustainable manufacturing

- High electrical insulation and breakdown strength

- Lead-free process compatibility

- Durable and reliable for long-term performance

- Semi-flexible bond layer absorbs stress and strain

- Built for extreme automotive, military, and aerospace conditions

TCLAD Inc. U.S. Mfg & Global

Innovation Center

1600 Orrin Rd, Prescott

WI 54021 USA

Phone: +1 715 262 5898

Email: sales.us@tclad.com

TCLAD Europe GmbH

Amelia-Mary-Earhart-Str. 8, 60549

Frankfurt am Main, Germany

Phone: +886 3 5635598

Email: sales.eu@tclad.com

TCLAD Technology Corp.

1 F., No. 5, Gongye E. 7th Rd.,

East Dist., Hsinchu City 300093,

Taiwan (R.O.C)

Phone: +886 3 5635598

Email: sales.asia@tclad.com