TCLAD IMS® Technology

Advanced Thermal Management with a Purpose

TCLAD’s Insulated Metal Substrate (IMS®) solutions are purpose-built to meet the most demanding thermal challenges. Engineered for high-performance, our IMS®/Thermal Clad Metal Core PCBs (MCPCBs) dramatically reduce thermal impedance and improve heat conduction – enabling more effective and efficient heat transfer compared to traditional FR4 PCBs. Beyond enhancing thermal performance, TCLAD IMS® products offer outstanding mechanical strength, making them significantly more durable than conventional FR4 PCBs.

TCLAD IMS® Technology excels in aerospace and defense applications such as radar power supplies, directed energy weapon power systems, and power supplies for drones, where reliability and thermal efficiency are mission-critical.

See the Difference with TCLAD IMS®

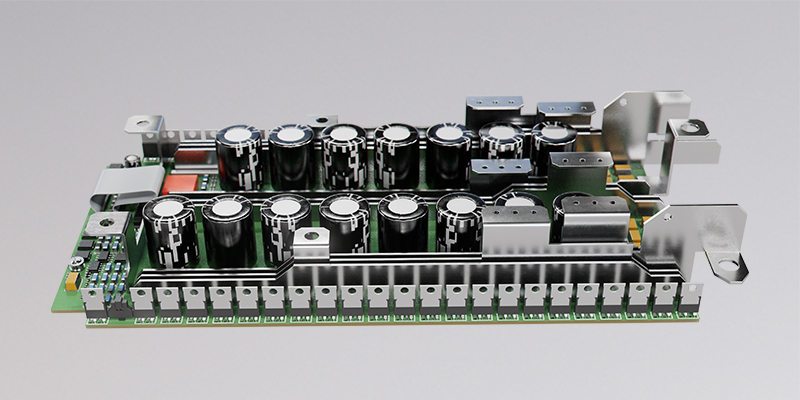

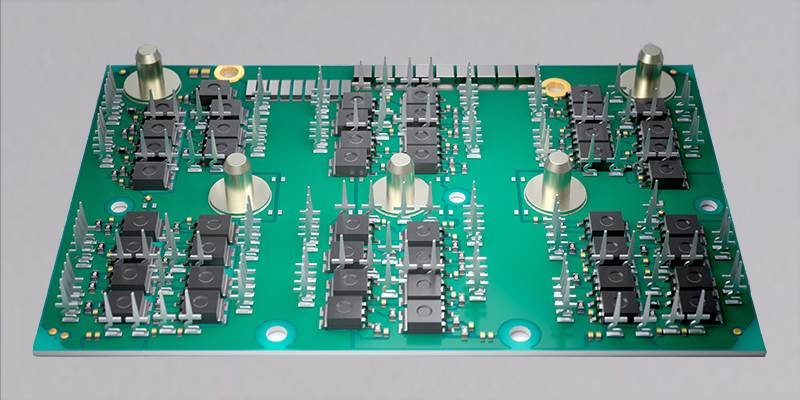

Independent testing proves TCLAD IMS® enhances heat spreading, effectively lowering temperatures of critical components.

TCLAD IMS® reduces hardware and production costs by simplifying PCB design and assembly.

- 66 Thru-Hole FETs

- 15 High Profile Capacitors

- 9 High Profile Bus Bars

- 3.4 lbs Total Weight

- 48 Surface Mount FETs

- 9 Low Profile Capacitors

- 5 Low Profile Bus Bars

- 0.82 lbs Total Weight

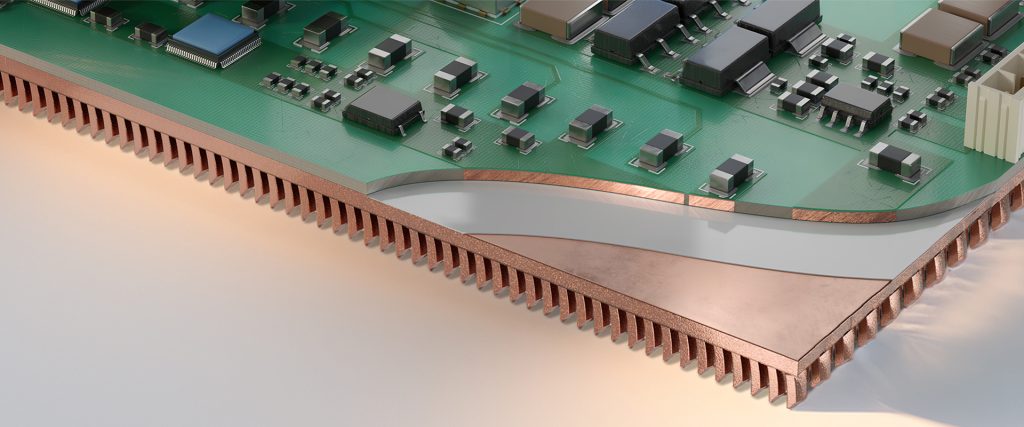

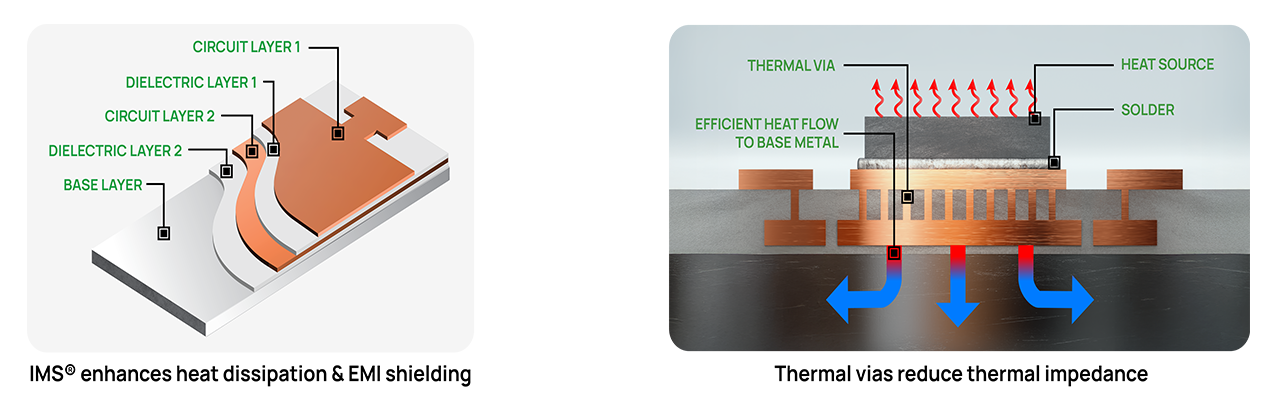

Anatomy of a TCLAD IMS® PCB

Standard IMS® construction consists of:

- Circuit Layers: Etched copper circuitry, with typical thicknesses ranging from 0.5 oz. to 10 oz. (17 – 360 µm). Although most designs incorporate 2 to 4 circuit layers, we have the advanced capability to fabricate IMS® boards with higher layer counts.

- Dielectric Layers: Provide excellent electrical insulation and outstanding thermal conductivity. Our patented dielectrics are formulated with polymer and ceramic. The dielectric layer also serves to bond the base metal and circuit layers together.

- Base Layer: Typically made of aluminum or copper, with thicknesses tailored to meet specific application demands. This layer functions as a heat sink or heat spreader, playing a critical role in TCLAD IMS® thermal management.

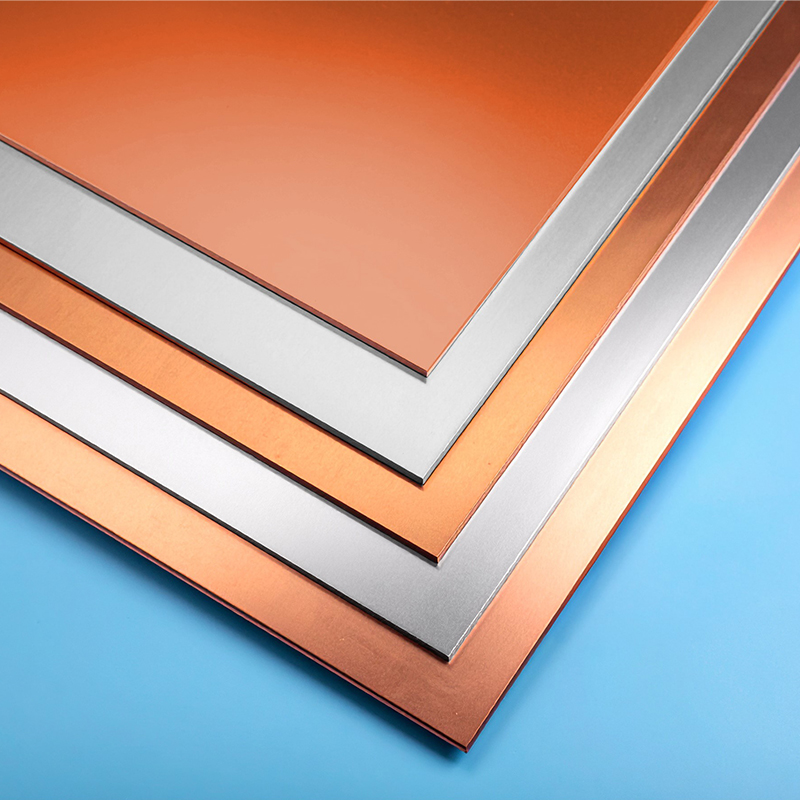

Thermal Clad Materials for IMS®/Metal Core PCBs (MCPCBs)

TCLAD offers a broad portfolio of IMS® dielectric materials available for direct purchase. We can also collaborate with you to custom-configure solutions that meet your specific requirements. From design concept and rapid prototyping to final production, we support every stage of development to ensure peak performance and manufacturability.

Copper or Aluminum Base Metals

Broad Portfolio of Patented Dielectric Materials

Custom IMS® Circuit Fabrication

Key Benefits of TCLAD IMS ®

- RoHS & REACH compliant, halogen-free, PFAS-free

- Lowers component operating temperatures

- Very low moisture absorption & outgassing

- Extends component life

- Supports higher power densities

- Enables smaller & uniquely shaped PCB designs

- Minimizes need for heat sinks, mounting hardware, and Thermal Interface Materials (TIMs)

- Supports high-current & high-voltage applications

- Improves mechanical durability and long-term reliability

- Reduces assembly complexity and cost

TCLAD Inc. U.S. Mfg & Global

Innovation Center

1600 Orrin Rd, Prescott

WI 54021 USA

Phone: +1 715 262 5898

Email: sales.us@tclad.com

TCLAD Europe GmbH

Amelia-Mary-Earhart-Str. 8, 60549

Frankfurt am Main, Germany

Phone: +886 3 5635598

Email: sales.eu@tclad.com

TCLAD Technology Corp.

1 F., No. 5, Gongye E. 7th Rd.,

East Dist., Hsinchu City 300093,

Taiwan (R.O.C)

Phone: +886 3 5635598

Email: sales.asia@tclad.com