Innovative Thermal Bridge Devices by TCLAD

TCLAD’s surface-mountable thermal bridge (SMTB) technology greatly improves heat spreading capacity across printed circuit boards (PCBs), reducing hotspots and enhancing overall thermal dissipation efficiency. This advancement enables designers to reduce system size and cost by eliminating the need for bulky heatsinks and complex thermal management methods.

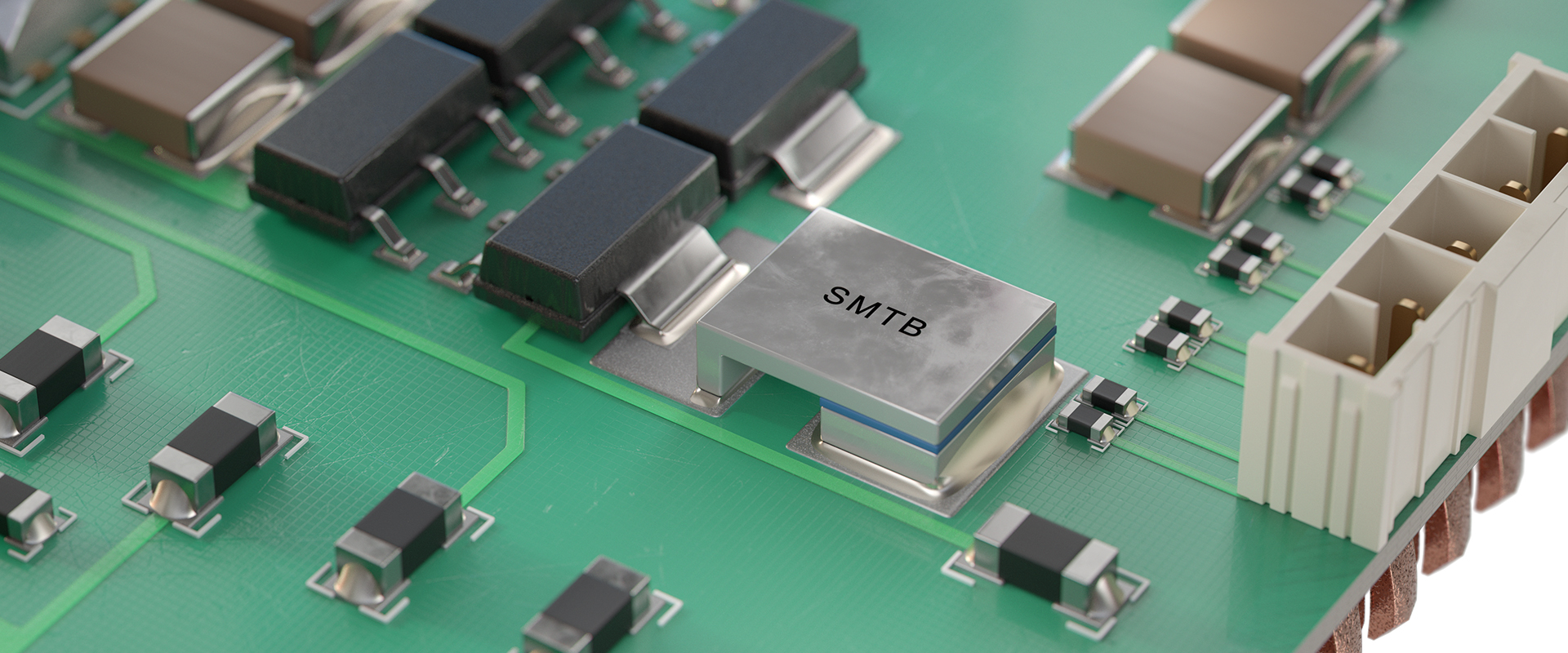

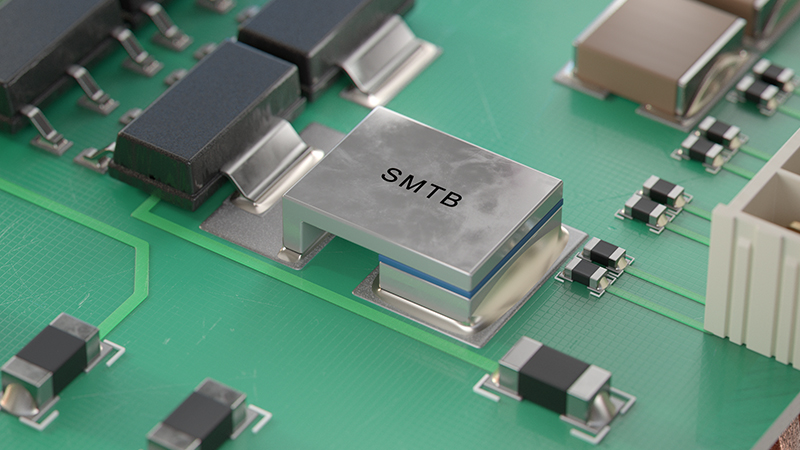

Lead Frame Surface Mount Thermal Bridge

Our open lead frame SMTB devices provide a compact and cost-effective method of efficiently channeling heat away from hotspots. Connected to a ground plane or chassis through PCB traces or grounding pads, these devices are ideal for dissipating heat in high-power, high-density printed circuit boards (PCBs).

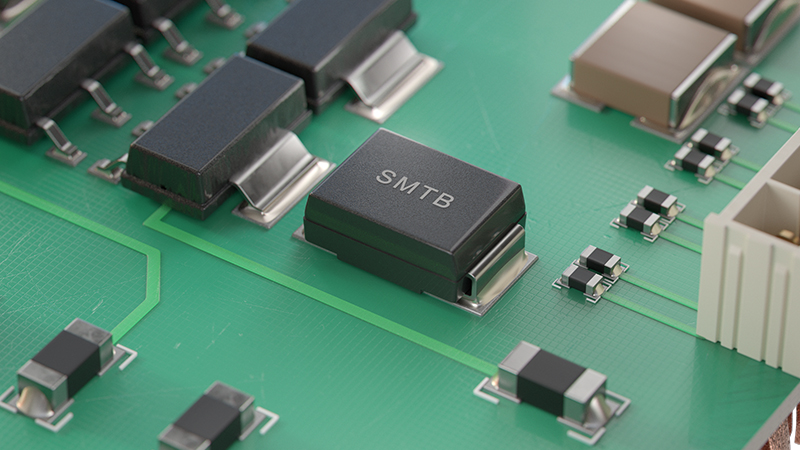

Molded Surface Mount Thermal Bridge

Our molded SMTB devices combine a lead frame structure, a thermally conductive core, and high-performance polymer composites to serve as compact, efficient heatsinks. They efficiently draw heat away from hotspots, channeling thermal energy through PCB traces and grounding pads to a ground plane for dissipation.

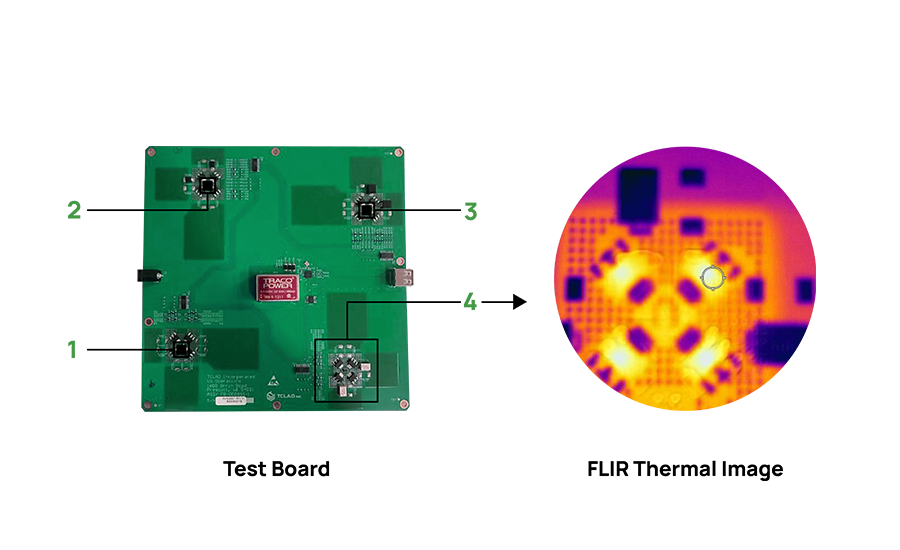

Putting TCLAD Thermal Bridges to the Test

TCLAD surface-mountable thermal bridges (SMTBs) are engineered to divert heat away from critical hotspots in power electronics. But how effective are they, really? To find out, we had them independently tested – and the results speak for themselves.

Test Setup

An FR4 test board was divided into four identical quadrants, each populated with four SOT-packaged, heat-generating components — ideal for simulating high thermal stress conditions.

Each quadrant featured a different SMTB configuration:

- Quadrant 1 (Lower Left): No thermal bridges (control)

- Quadrant 2 (Upper Left): Three SMTBs (P/N SMTB2114P30E)

- Quadrant 3 (Upper Right): Three SMTBs (P/N SMTB3123P30E)

- Quadrant 4 (Lower Right): Three SMTBs (P/N SMTB2920P30M)

Thermal imaging was performed using a FLIR infrared camera, ensuring accurate, non-contact temperature measurements across all quadrants.

The Results

| Quadrant | Configuration / Part # | Thermal Resistance (°C/W) | Max Component Surface Temperature | Temperature Reduction Compared to Control Quadrant |

|---|---|---|---|---|

| 1 | No Thermal Bridges (Control) | — | 279°F (137.2°C) | — |

| 2 | SMTB 2114P30E | 4 | 251°F (121.7°C) | -28°F (-15.5°C) |

| 3 | SMTB3123P30E | 1.1 | 245°F (118.3°C) | -34°F (-18.9°C) |

| 4 | SMTB2920P30M | 0.7 | 237°F (113.9°C) | -42°F (-23.3°C) |

Built for Performance, TCLAD SMTBs Delivered Under Pressure!

TCLAD surface-mountable thermal bridges (SMTBs) made a measurable impact – reducing component temperatures by up to 42°F (23.3°C) compared to the control quadrant without thermal bridges. Larger SMBT devices provided even greater cooling, with the large open lead frame (P/N SMTB2920P30M) showing the most significant effect.

TCLAD Flyer – Hot Spots & Cool Tricks

Key Benefits of TCLAD Thermal Bridges

- Compatible with Surface-Mount Technology & Processes

- Simple Integration into Standard PCB Layouts

- Wide Operating Temperature Range (-55°C to 150°C)

- High Voltage Withstand

- Low Thermal Resistance

- Low Capacitance / Ideal for High-Frequency RF Applications

- Tape & Reel Packaging for Automated Pick-and-Place Assembly

TCLAD Inc. U.S. Mfg & Global

Innovation Center

1600 Orrin Rd, Prescott

WI 54021 USA

Phone: +1 715 262 5898

Email: sales.us@tclad.com

TCLAD Europe GmbH

Amelia-Mary-Earhart-Str. 8, 60549

Frankfurt am Main, Germany

Phone: +886 3 5635598

Email: sales.eu@tclad.com

TCLAD Technology Corp.

1 F., No. 5, Gongye E. 7th Rd.,

East Dist., Hsinchu City 300093,

Taiwan (R.O.C)

Phone: +886 3 5635598

Email: sales.asia@tclad.com